Automatic lens edgers revolutionize the optical industry, offering efficiency and precision. These advanced machines not only streamline lens production but also ensure superior quality by minimizing human error. Whether you’re a lab owner or an optician, understanding the advantages of automatic lens edgers can significantly impact your workflow. Explore how these tools can enhance your business, improve customer satisfaction, and save valuable time in a competitive market.

Advantages of Automatic Lens Edgers

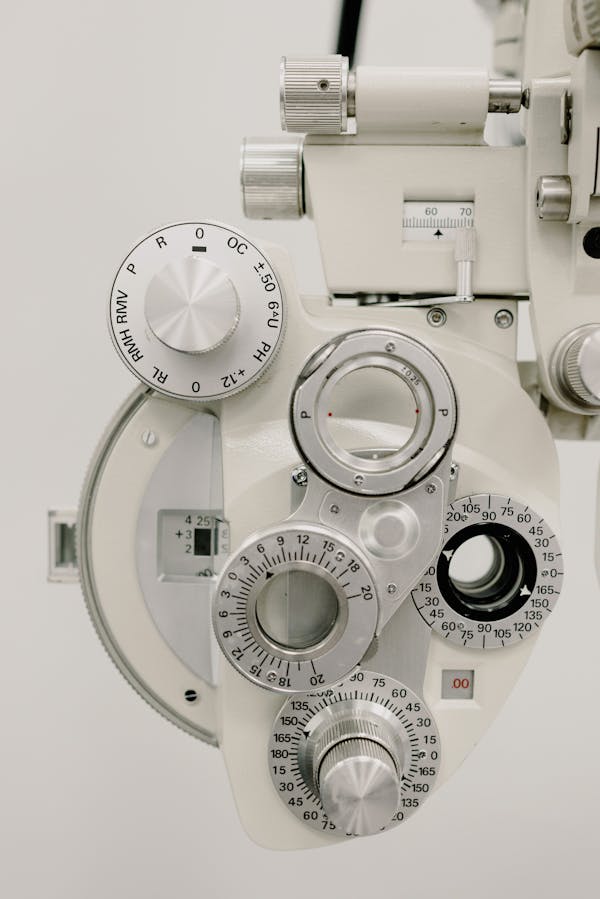

Automatic lens edgers have transformed the lens manufacturing process by enhancing productivity, precision, and efficiency. These advanced machines streamline lens edging operations, significantly reducing manual workload. This automation allows opticians to produce high-quality lenses consistently, minimizing human error. By ensuring precise measurements and cuts, lens edgers deliver superior optical products tailored to individual patient needs. Learn more now about how these innovations in technology contribute to producing flawless lenses with impressive speed.

Also to see : Securing Investment: Top Strategies for UK Healthcare Startups to Attract Funding

Moreover, automatic lens edgers improve workflow efficiency within optical labs. They offer increased patient throughput by allowing professionals to focus on customer care rather than time-consuming manual tasks. This process optimization is vital for practices aiming to maintain high volumes without sacrificing quality. The equipment’s ability to handle various lens materials, including plastic and polycarbonate, makes them versatile assets for any optical business. Additionally, integrating advanced edging machines like those from Visionix with optical software systems can further enhance efficiency by automating data transfers and reducing the potential for errors. The future of optical technology looks promising with continuous improvements in these automated systems.

Advanced Features of Lens Edging Technology

Key Specifications of Top Lens Edgers

Modern lens edging technology offers a suite of features that have revolutionized opticianry. Top-of-the-line edgers boast innovative automation, allowing detailed customization and precise results. They accommodate various materials and lens types, from high-index to polycarbonate, ensuring versatility. Equipped with advanced tracing and centering capabilities, these machines deliver unparalleled precision, crucial for complex frame designs. The SE-90990 Supra, for example, exemplifies this with its multifaceted approach.

This might interest you : Driving change: essential strategies for uk car rental companies to succeed in the electric vehicle era

Safety and User-Friendly Design Features

With safety at the forefront, automatic lens edgers incorporate user-focused designs. Enhanced safety mechanisms protect operators, while intuitive interfaces facilitate ease of use, minimizing manual errors. Features like intelligent shape modification ensure that even novice users can achieve expert-level results. Many models prioritize accessibility, enabling seamless operation without extensive training.

Energy-Efficient Models and Their Benefits

As sustainability becomes increasingly important, energy-efficient edgers are gaining traction. These models reduce energy consumption, lowering operational costs and environmental impact. Leveraging eco-friendly technologies, such machines offer significant benefits by aligning with green practices without compromising performance. Energy-efficient edgers represent a strategic investment for modern optical labs aiming for sustainability and cost-efficiency.

Maintenance and Operational Considerations for Lens Edgers

Routine Maintenance Practices for Longevity

Proper maintenance of a lens edger not only extends its lifespan but also ensures consistent performance and precision. Regular cleaning is essential—dust and debris accumulation can impair functionality. Ensuring the unit’s moving parts are lubricated will optimize efficiency and reduce wear. Inspect spindle motors periodically for wear and recalibrate your edger every few months to maintain cutting accuracy.

Common Issues and Troubleshooting Solutions

Lens edgers may experience issues such as misalignment or cutting inaccuracies. These can often be resolved through simple recalibration. If motor malfunctions occur, checking connections and ensuring the correct voltage can help. Additionally, replace dull edging wheels promptly to prevent further complications and achieve precise cuts.

Importance of Proper Training for Optimal Use and Handling

Training technicians is crucial for maximizing the performance of lens edgers. Understanding operational procedures and identifying signs of wear or impending faults can prevent major disruptions. Hands-on training ensures users can tackle basic troubleshooting efficiently, keeping operations running smoothly and minimizing downtime.